News

-

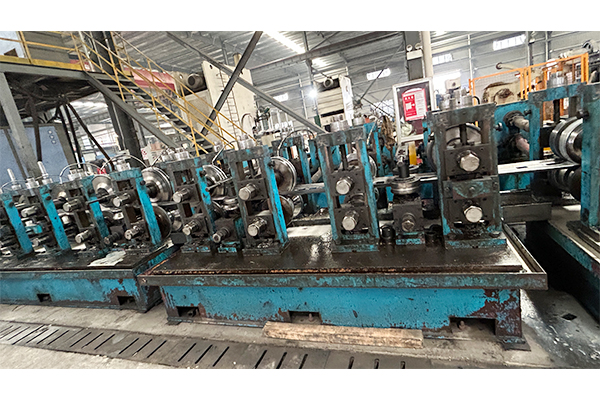

After long-term use and running-in, does a used welded pipe machine have fewer faults and more stable production than a new machine?

According to actual production data, the failure interval of used welded pipe machines is usually longer than that of new machines of the same model.

Learn More2025-08-19 -

When a tube mill is used to grind chemical raw materials, can it ensure that the material fineness meets the standards and process requirements?

The parameters of the used tube mill, such as feed rate, rotation speed, and grinding time, need to be precisely set according to the characteristics of the raw materials.

Learn More2025-08-18 -

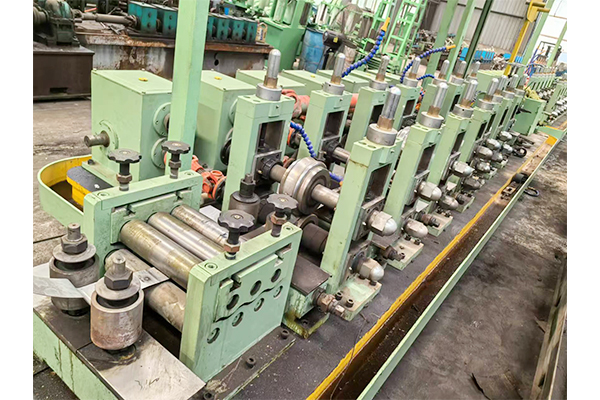

Does the automation level of a used 50 enlarge 76 high-frequency welding pipe mill meet the integration requirements of modern production lines?

Although a used 50 enlarge 76 high-frequency welding pipe mill may not initially be equipped with the most advanced automation systems, with appropriate upgrades and retrofits, these machines can reach or even exceed current automation levels.

Learn More2025-08-12 -

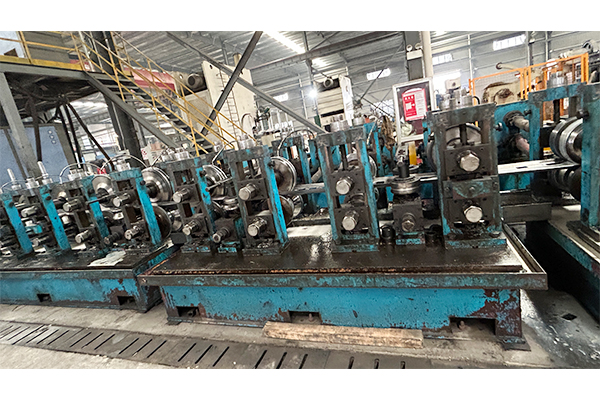

How does a used imported stainless steel from Europe high-frequency welded pipe mill facilitate adjustment when processing stainless steel pipes of varying specifications?

Through its flexible design and intelligent features, used imported stainless steel from Europe high-frequency welded pipe mills offer exceptional ease of adjustment when processing stainless steel pipes of varying specifications.

Learn More2025-08-11 -

How can professional refurbishment assess the remaining life of a 100-square-meter tube mill's barrel, gears, and bearings and ensure long-term operational reliability?

In the grand landscape of modern industrial powder processing, a 100-square-meter used tube mill represents far more than just the recycle of a large piece of equipment.

Learn More2025-08-05 -

How can used slitting machines help small and medium-sized enterprises quickly enter the materials processing market by reducing initial investment costs?

In the modern industrial manufacturing chain, precision cutting and slitting of materials is a critical link in determining final product quality and production efficiency.

Learn More2025-08-04